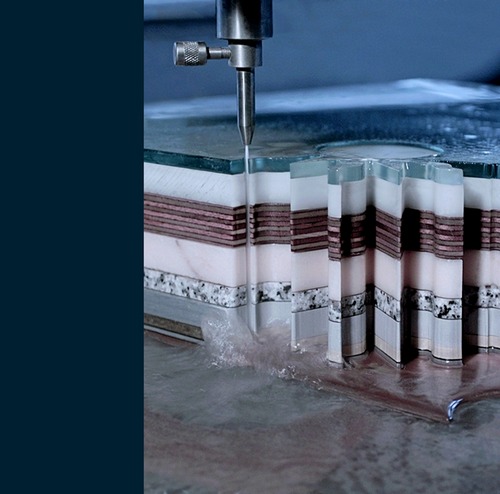

Waterjet Technology

Waterjet technology is the only method that makes it possible to cut materials without thermal stress (cold cutting). With the high pressure of water (4,000 bar) and the cutting capacity of the special emery, waterjet machines cut with high precision a huge range of materials.

Water cutting is based on CNC technology, like other popular cutting machines and is an ideal tool for those interested in having the best cutting quality in any material and thickness.

Materials and Waterjet

The water cutting successfully handles all common materials such as:

- Ferrous: stainless steel, iron sheets, structural steels, etc.

- Non-Ferrous: aluminum, brass, copper, titanium.

- Glass, triplex, crystals.

- Marble, granite, ceramic tiles.

- Wood, plywood.

- Plastics, nylon, PVC, tires.

- Corian, Plexiglass, Etalbon.

- Concrete, rocks.

- Composite materials, carbon fiber.

- Leather, fabrics, food.

* In soft materials the cutting is done with high water pressure, without emery.

Why Waterjet

- Ability of cutting very thick materials.

- Application to all materials without exception.

- Very good cutting quality.

- Low initial investment cost.

- It does not create thermal stress on the materials.

- No toxic gases are released.

- Environmentally friendly.